If you think inventory-sharing is the silver bullet to your overstock woes, you’re missing a vital aspect of its potential.

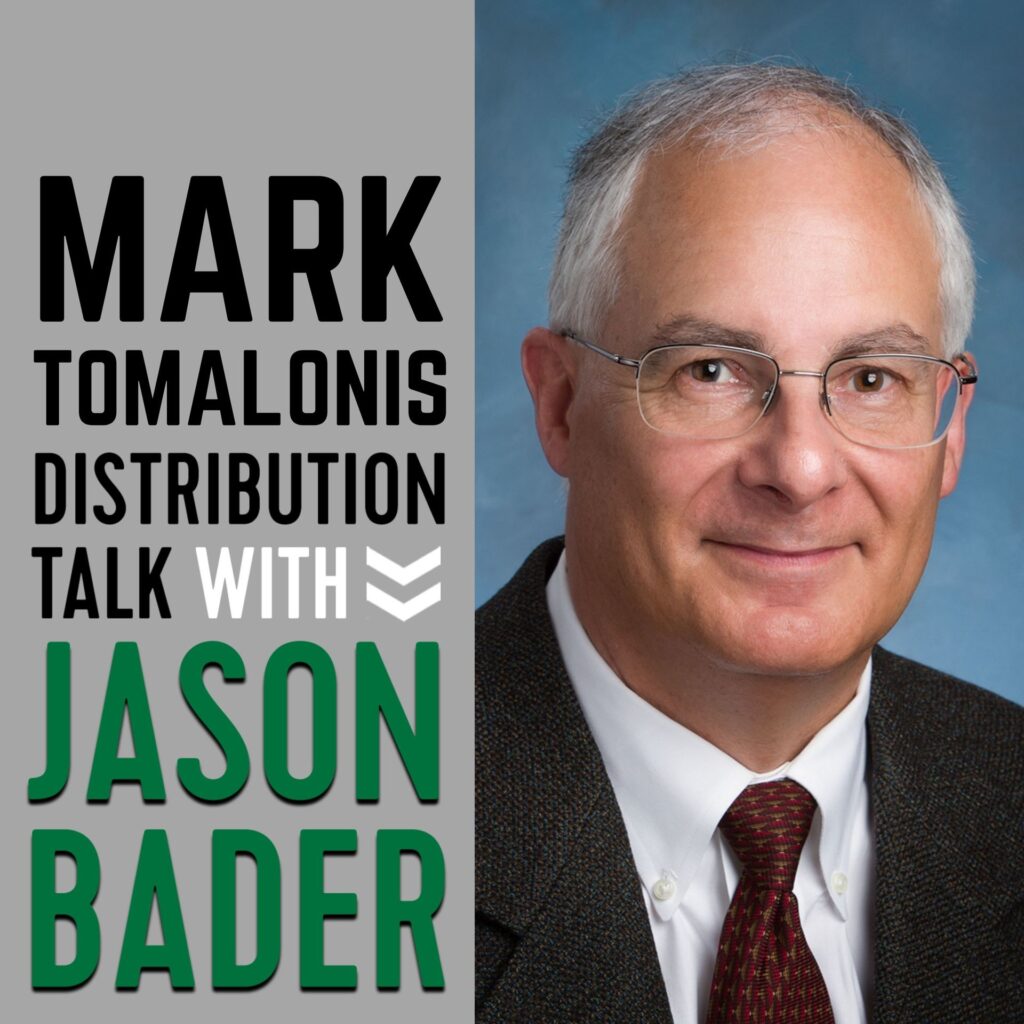

Mark Tomalonis, president of WarehouseTWO, says the platform performs best as a collaborative space, one in which the power of peer inventories helps members source non-stock, difficult-to-purchase items. I sat down with Mark to uncover how inventory-sharing works and why it’s good for business.

We help distributors of any size act as if he owns all the inventory in his catalog, says Mark, of the business he started on a whim back in 2005.

The WarehouseTWO model doesn’t just provide a second life for unproductive inventory or deadstock. Instead, it connects buyers with sellers, allowing both to defend against backorder delays, high-quantity minimums, and disappointed customers, all without having to keep the actual product in hand.

Inventory sharing increases asset efficiency and operational efficiency for a network of pure wholesale distributors.

***

Distribution Talk is produced by The Distribution Team, a consulting services firm dedicated to helping wholesale distribution clients remove barriers to profitability, generate wealth and achieve personal goals.

https://www.distributionteam.com

This episode was edited & mixed by The Creative Impostor Studios.

Connect with Jason on LinkedIn: https://www.linkedin.com/in/jasonbader/

Connect with Mark on LinkedIn:

https://www.linkedin.com/in/marktomalonis/

***

While not the first company to come up with the idea, WarehouseTWO is one of the prime players in this small niche, managing to grow even as big names like IBM bow out of the market.

In an age when it seems like everyone’s out to shake up an industry, Mark credits his company’s staying power to his philosophy of supporting authorized regional distributors. WarehouseTWO exists to defend and support a manufacturer’s assigned distribution channel, he says. We don’t exist to disrupt it.

Nor does WarehouseTWO exist to solve inventory management problems in a vertical fashion akin to ERP models. He wants clients to think horizontally by exposing their inventory to tens of thousands of additional end customers, taking what’s in stock and making it available to dozens of pure distributors in other parts of the country.

Besides, to his way of thinking, there’s only three ways to rectify surplus issues.

Number one: prevent it. Mark urges listeners to put systems, policies, and resources or talent into place so that you don’t end up with the extra stock in the first place. Number two: rent the dumpster. And his number three tip for avoiding inventory overload? There is no number three, he laughs. Nobody wants your purchasing mistakes.

Listen in for more inventory insight from Mark and find out how WarehouseTWO can take the sting out of number three.